When talking about the phrase “blood vessel”, everyone is familiar with it. Blood vessels are the channels of human lives and the source of vitality. When blood flows in blood vessels, human body gets a steady stream of energy. If you compare a concrete dam to a person, then the temperature measuring fibers installed within are like the blood vessels of the dam. Through the full cycle of comprehensive sensing the fine changes of concrete temperature, they provide a source of data for intelligent temperature control.

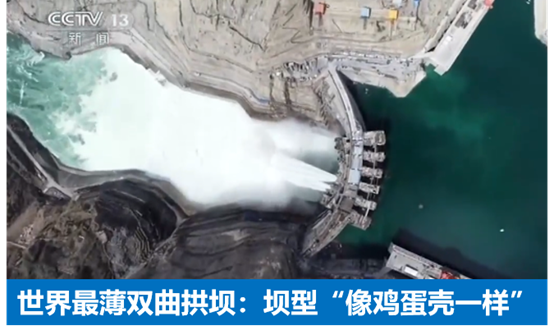

Wudongde Hydropower Station is the seventh-largest hydropower station in the world. The dam is a concrete double-curved arch dam with a maximum height of 270 m.

For a 300 m-level super high arch dam, temperature control and crack prevention during the construction period are huge challenges. As for Wudongde Hydropower Station, the first major challenge for temperature control and crack prevention is its design as an ultra-thin arch dam. The thickness-to-height ratio of the Wudongde arch dam is only 0.19, which is the world’s thinnest 300 m-level super-high arch dam. The shape of the dam is like an eggshell. Studies have shown that the thinner the arch dam, the greater the influence of temperature loads on it, and the more difficult it is to control the temperature to prevent cracking.

The second major challenge is the dry and hot river valley environment where the dam has to be constructed. The highest temperature at the Wudongde Hydropower Station site can reach 40 degrees Celcius, the annual temperature is higher than 35 degrees Celcius for more than 160 days, and the minimum humidity is less than 20%. Under dry and hot conditions, concrete is more likely to crack.

The third major challenge is that the whole Wudongde Hydropower Station adopts low-heat cement concrete, which is the first time in the construction history of 300 m-class arch dams in the world. The law of the real temperature field inside the low-heat cement concrete is not yet clear, which exceeds the existing specifications, thus there is no existing temperature control experience to follow. Therefore, the fine control of the temperature of the Wudongde Dam is particularly important during the construction period.

The premise of formulating reasonable and effective temperature control measures is to obtain the true temperature distribution of the concrete. However, in dam concrete, thermometers are often arranged discreetly and sporadically, and the acquired temperature monitoring data are few, which cannot represent the true temperature distribution of the dam.

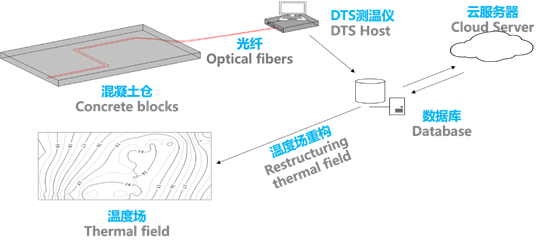

The distributed optical fiber temperature measurement technology came into being from the application at the Wudongde Dam. Distributed optical fibers can not only monitor the real-time temperature continuously, but also have a series of advantages such as numerous measuring points, high precision, and remote monitoring. The Wudongde Dam optical fiber temperature measurement system is mainly composed of a DTS temperature measurement host, distributed optical fiber, data network, cloud platform, and human-computer interaction interface. Realizing the reconstruction of concrete temperature field is based on real temperature data.

In the history of concrete temperature monitoring, the use of thermometers and optical fiber temperature measurement has a long history. However, in the past construction projects, experiences played a big role under the conditions where the layout and quantity of typical representative elevations in typical dam sections are often certain. The temperature distribution obtained in this way is not necessarily real, and it is often not the optimal way.

How can we obtain the true temperature field with a fixed number of temperature sensors? We found that the key is to arrange each temperature sensor to the optimal position and make full use of its temperature information. Just like the blood vessels of the human body, they are distributed in legitimate positions so that every part of the body can get enough energy. Based on this, we proposed a global dam temperature measurement method. The main principle is: under the appropriate number of temperature sensors, optimally arrange their positions, and monitoring data through temperature sensors, reconstruct the temperature field, finally achieving the goal of reflecting the real concrete temperature field. Based on this result, we have also obtained the corresponding invention patent.

In addition, we have simultaneously developed a software for the global dam temperature measurement method. By continuously optimizing the location and number of temperature measurement points, we can realize the real reconstruction of the concrete temperature field. Based on the real temperature data obtained by the temperature measurement fibers, an algorithm for reconstructing the real temperature field of the dam concrete is proposed. The core of the algorithm is mainly an optimized interpolation algorithm. It is equivalent to selecting an optimal way to deliver energy to all parts of the body after the distribution of the blood vessels in the human body is determined. In our research, we compared different interpolation algorithms and found that the concrete real temperature field reconstructed by the natural neighbor algorithm is the most consistent with the known thermometer monitoring data. Therefore, based on the distributed optical fiber monitoring data and the natural lead point interpolation algorithm, the real temperature field of the Wudongde Dam was reconstructed, and the temporal and spatial changes of the reconstructed temperature field were consistent with the scene. The differences between the temperature monitoring data and the reconstructed temperature data are within one degree Celcius, most of which are less than 0.5 degrees Celcius. The reconstruction accuracy is high. A Wudongde optical fiber online monitoring platform has been built to monitor and track real-time temperature distributions, providing a basis for accurate temperature control. We have also obtained the corresponding software copyright.

Based on the reconstruction of the temperature field and the method of global dam temperature measurement, combining with the intelligent water supply system, the Wudongde Dam has achieved controllable maximum concrete temperature, adjustable temperature control process, and optimizable temperature control measures. Furthermore, the Wudongde Dam has accomplishments as follows: the maximum temperature compliance rate is 99.85%, the cooling rate compliance rate is 99.15%, and the temperature change amplitude compliance rate in the temperature control stage is 96.71%. We are proud to say that there is no temperature crack in the Wudongde Dam.

In addition, a simulation analysis of the whole process of the Wudongde Dam was conducted using the real temperature field information. Various optimization suggestions were put forward for the dam to protect the safe operation of the dam.

Currently, the Wudongde Dam has carried out its third stage of water storage, and the water storage elevation reaches EL965 m, which is only one step away from the normal storage level of EL975 m. All monitoring data show that the Wudongde Dam is running as expected. All indicators are better than similar high dams, implying that the overall safety is guaranteed.

Based on the innovative achievements of optical fiber temperature measurement technology, we have also obtained corresponding intellectual property rights. Five invention patents, one technical standard, and one software copyright have been authorized. One paper has been published and another one was under revision.

Our main results are summarized as follows: based on optical fiber monitoring, we have invented a global dam temperature measurement method, proposed a temperature field reconstruction method, realized real temperature field reconstruction, personalized regulating intelligent water flow, and realistic simulation of the dam’s behaviors.

On June 29, 2020, the first unit of the Wudongde Hydropower Station was put into operation for power generation. Chairman Jinping Xi has emphasized that Wudongde Hydropower Station is a major national project for the implementation of the “West-to-East Power Transmission”, and we should build high-quality projects, climb new heights of science and technology, and better benefit the people. This is an affirmation to the the Wudongde Dam as well as to the countless hydropower-related people working behind the scenes. As a witness to the construction of the Wudongde project, I am very fortunate and honored. In future, I will stick to my original aspirations and keep moving forward.

That’s it. Thank you.